Products

Stainless Steel Screw Into Chipboard

Product Description

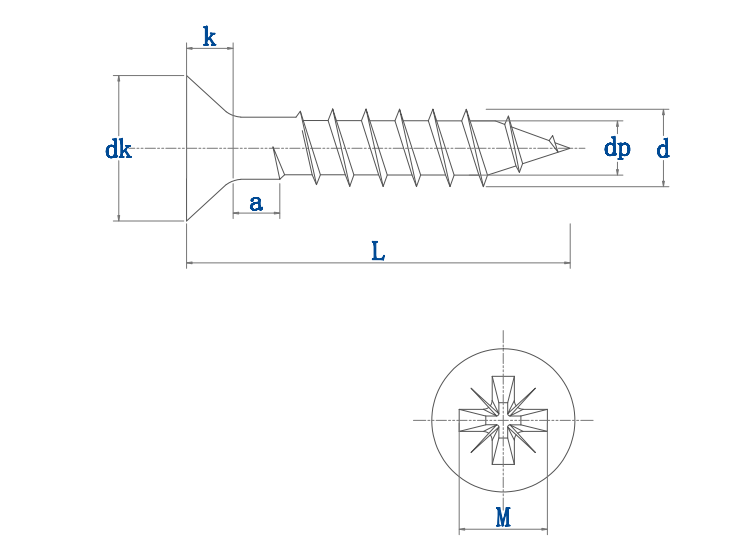

| Product Name | Stainless Steel Screw Into Chipboard |

| Material | Made from 304 stainless steel, these screws have good chemical resistance and may be mildly magnetic. They are also known as A2 stainless steel. |

| Head Type | Countersunk Head |

| Drive Type | Cross Recess |

| Length | Is measured from the head |

| Application | Chipboard Screws are suitable for light construction tasks, such as installing panels, wall cladding, and other fixtures where a strong and durable fastener is required, and due to their ability to provide a stronghold, they are widely used in the assembly of chipboard and MDF (medium-density fiberboard) furniture. |

| Standard | Screws that meet ASME or DIN 7505(A) with standards for dimensions. |

Advantages of Stainless Steel Chipboard Screws

1. The countersunk/ double countersunk head: The flat head makes the chipboard screw stay level with the material. In particular, the double countersunk head is designed for increased head strength.

2. The coarse thread: compared with other kinds of screws, the thread of the screw MDF is coarser and sharper, which digs deeper and more tightly into the soft material such as particleboard, MDF board, etc. In other words, this helps more part of the material to be embedded in the thread, creating an extremely firm grip.

3. The self-tapping point: The self-tapping point makes the screw of particle boar more easily driven into the surface without a pilot drill hole.

Frequently Asked Questions

Chipboard screws are specifically designed for use with chipboard and other types of particle board. They are ideal for furniture assembly, cabinetry, and other woodworking projects involving composite materials.

Chipboard screws come in various sizes, typically specified by length and gauge. Common lengths range from 1.2 inches to 4 inches, while gauges include #6, #8, #10, and #12.

The gauge of the screw should correspond to the thickness of the materials being joined. Thicker materials generally require screws with larger gauges for optimal performance and security. Common gauges include #6 for lighter tasks, #8 and #10 for medium-duty applications, and #12 for heavier tasks.

Yes, chipboard screws can come with various head types (e.g., countersunk, pan head), thread types (e.g., coarse thread, fine thread), and finishes (e.g., Zinc yellow-plated, black phosphate) to suit different applications and environments.

Chipboard Screws are shorter and with more closely spaced threads. Designed specifically for use with chipboard and other types of particleboard.

Chipboard Screws are shorter and with more closely spaced threads. Designed specifically for use with chipboard and other types of particleboard.

| For Nominal Thread Diameter | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | ||

| d | max | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | |

| min | 2.25 | 2.75 | 3.2 | 3.7 | 4.2 | 4.7 | 5.7 | ||

| P | Pitch(±10%) | 1.1 | 1.35 | 1.6 | 1.8 | 2 | 2.2 | 2.6 | |

| a | max | 2.1 | 2.35 | 2.6 | 2.8 | 3 | 3.2 | 3.6 | |

| dk | max=nominal size | 5 | 6 | 7 | 8 | 9 | 10 | 12 | |

| min | 4.7 | 5.7 | 6.64 | 7.64 | 8.64 | 9.64 | 11.57 | ||

| k | 1.4 | 1.8 | 2 | 2.35 | 2.55 | 2.85 | 3.35 | ||

| dp | max=nominal size | 1.5 | 1.9 | 2.15 | 2.5 | 2.7 | 3 | 3.7 | |

| min | 1.1 | 1.5 | 1.67 | 2.02 | 2.22 | 2.52 | 3.22 | ||

| Socket No. | 1 | 1 | 2 | 2 | 2 | 2 | 3 | ||

| M | 2.51 | 3 | 4 | 4.4 | 4.8 | 5.3 | 6.6 | ||