Products

Stainless Steel Phillips Flat Head Self Drilling Screws

Product Description

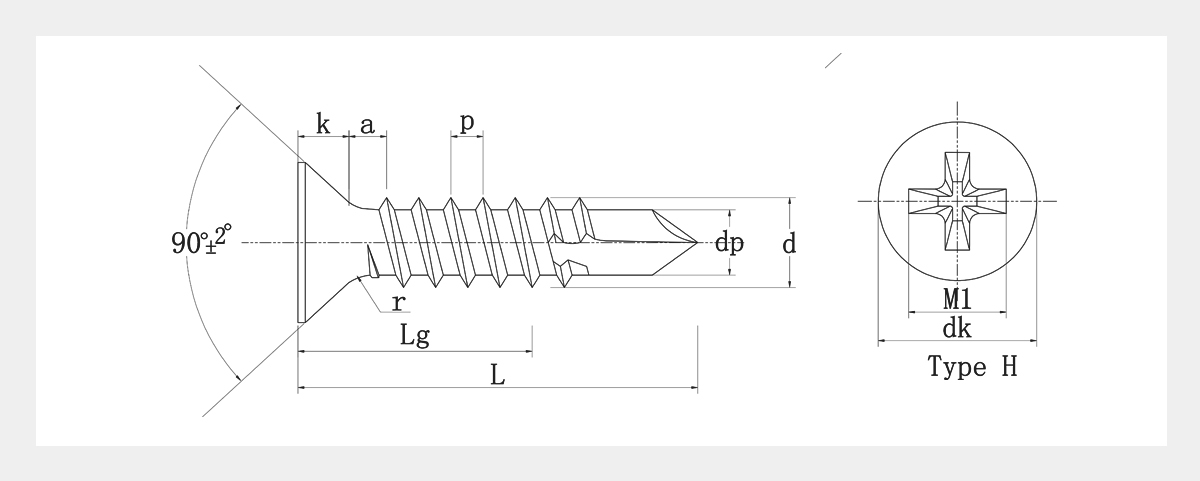

| Product Name | Stainless Steel Phillips Flat Head Self Drilling Screws |

| Material | Made from stainless steel, these screws have good chemical resistance and may be mildly magnetic. |

| Head Type | Countersunk Head |

| Length | Is measured from the top of head |

| Application | They're not for use with aluminum sheet metal. All are beveled under the head for use in countersunk holes. Screws penetrate 0.025" and thinner sheet metal. |

| Standard | Screws that meet ASME B18.6.3 or DIN 7504-O with standards for dimensions. |

Applications of Stainless Steel Countersunk Head Self-Drilling Screws

Stainless steel countersunk head self-drilling screws are versatile fasteners used in a wide range of applications due to their durability, corrosion resistance, and ability to create a flush finish. Their self-drilling capability eliminates the need for pre-drilling, saving time and ensuring precision in various tasks.

1. Construction and Building Projects

Roofing: Secure metal sheets, panels, and other roofing materials to structures.

Framing: Fasten wood or metal frames with precision and a smooth surface finish.

Decking: Provide a clean, flat finish for outdoor decking projects.

2. Metalworking

Metal-to-Metal Fastening: Ideal for joining steel components in construction, industrial equipment, or vehicle manufacturing.

Aluminum Structures: Used for assembling aluminum frameworks or panels without corrosion concerns.

3. Woodworking

Wood-to-Metal Connections: Securely attach wood to metal beams or frames.

Furniture Assembly: Create professional-grade, flush finishes in furniture construction.

4. Marine and Outdoor Applications

Boats and Ships: Secure components in marine environments where saltwater corrosion resistance is critical.

Fencing and Facades: Fasten external installations exposed to weather and moisture.

5. Industrial Machinery and Equipment

Assembly Lines: Assemble machines and devices requiring precision and durability.

Repairs and Maintenance: Replace worn or corroded fasteners with robust stainless steel screws.

6. HVAC and Electrical Installations

Ductwork: Fasten air ducts and metal frames securely.

Paneling: Attach electrical panels and components efficiently.

| Thread Size | ST2.9 | ST3.5 | ST4.2 | ST4.8 | ST5.5 | ST6.3 | ||

| P | Pitch | 1.1 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 | |

| a | max | 1.1 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 | |

| dk | max | 5.5 | 7.3 | 8.4 | 9.3 | 10.3 | 11.3 | |

| min | 5.2 | 6.9 | 8 | 8.9 | 9.9 | 10.9 | ||

| k | max | 1.7 | 2.35 | 2.6 | 2.8 | 3 | 3.15 | |

| r | max | 1.2 | 1.4 | 1.6 | 2 | 2.2 | 2.4 | |

| Socket No. | 1 | 2 | 2 | 2 | 3 | 3 | ||

| M1 | 3.2 | 4.4 | 4.6 | 5.2 | 6.6 | 6.8 | ||

| M2 | 3.2 | 4.3 | 4.6 | 5.1 | 6.5 | 6.8 | ||

| dp | 2.3 | 2.8 | 3.6 | 4.1 | 4.8 | 5.8 | ||

| Drilling range(thickness) | 0.7~1.9 | 0.7~2.25 | 1.75~3 | 1.75~4.4 | 1.75~5.25 | 2~6 | ||