Products

Stainless Chipboard Screws

Product Description

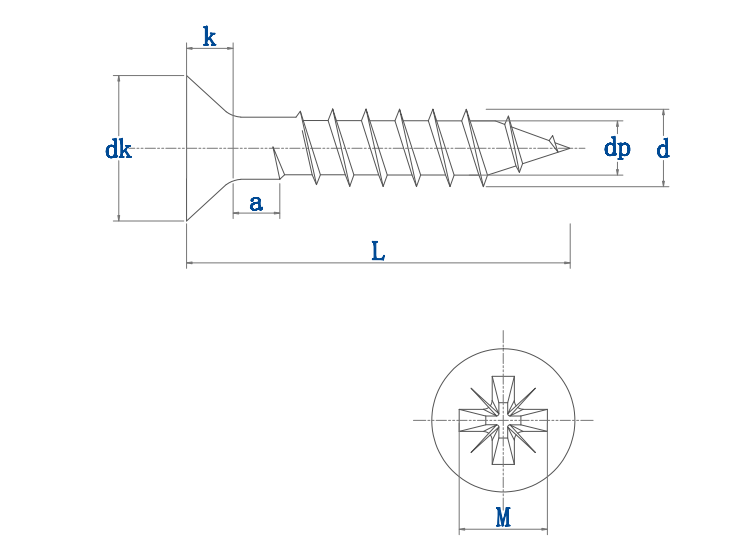

| Product Name | Stainless Chipboard Screws |

| Material | Made from 304 stainless steel, these screws have good chemical resistance and may be mildly magnetic. They are also known as A2 stainless steel. |

| Head Type | Countersunk Head |

| Drive Type | Cross Recess |

| Length | Is measured from the head |

| Application | Chipboard Screws are suitable for light construction tasks, such as installing panels, wall cladding, and other fixtures where a strong and durable fastener is required, and due to their ability to provide a stronghold, they are widely used in the assembly of chipboard and MDF (medium-density fiberboard) furniture. |

| Standard | Screws that meet ASME or DIN 7505(A) with standards for dimensions. |

Sizes of Chipboard Screws

Chipboard screws come in a range of accommodate different material thicknesses and a wide range of project requirements. The chipboard screws sizes are typically specified using two main parameters: length and gauge, defined as follows:

Length: The length of chipboard screw is measured from the tip of the threaded part to the end, or the whole body from point to point. When selecting the appropriate length, ensure the screw is long enough to penetrate both materials, providing sufficient thread engagement without protruding through the other side.

Gauge: Gauge refers to the diameter of the screw. Common gauges for chipboard screws include #6, #8, #10, and #12. Thicker materials for connection generally require screws with larger gauges for optimal performance and better security.

Choosing the Right Chipboard Screw for Your Project

Choosing the right particleboard screws for your project will ensure successful fastening, the following factors will help you for the right choice:

Length: Choose a screw length that allows it to penetrate the top material and attach itself securely to the underlying chipboard.

Thread Type: Depending on the specific application, you might opt for a single or twin-thread chipboard screw. Twin-thread screws tend to drive in faster, while single-thread screws offer better holding power.

Head Type: SS Chipboard screws come with a variety of head types, including countersunk, pan head. Consider the aesthetics of your project and the type of machine you’ll be using to drive the screw.

Material Thickness: Measure and select a screw length that allows for proper penetration through both materials being connected.

Load-bearing capacity: For load-bearing applications, choose screws with a larger gauge and length to ensure a secure and durable connection.

Environmental Conditions: In outdoor or high-moisture environments, choose chipboard screws made from corrosion-resistant materials, such as stainless steel chipboard screws.

Type of Wood: Different woods have varying densities. Adjust the screw size accordingly to achieve the most suitable holding power.

Want to purchase wholesale chipboard screws?

Learn more about the fastening with the professionals at AYA Fasteners. We offer high-quality chipboard screws and a diverse range of fasteners for different industry applications.

| For Nominal Thread Diameter | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | ||

| d | max | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | |

| min | 2.25 | 2.75 | 3.2 | 3.7 | 4.2 | 4.7 | 5.7 | ||

| P | Pitch(±10%) | 1.1 | 1.35 | 1.6 | 1.8 | 2 | 2.2 | 2.6 | |

| a | max | 2.1 | 2.35 | 2.6 | 2.8 | 3 | 3.2 | 3.6 | |

| dk | max=nominal size | 5 | 6 | 7 | 8 | 9 | 10 | 12 | |

| min | 4.7 | 5.7 | 6.64 | 7.64 | 8.64 | 9.64 | 11.57 | ||

| k | 1.4 | 1.8 | 2 | 2.35 | 2.55 | 2.85 | 3.35 | ||

| dp | max=nominal size | 1.5 | 1.9 | 2.15 | 2.5 | 2.7 | 3 | 3.7 | |

| min | 1.1 | 1.5 | 1.67 | 2.02 | 2.22 | 2.52 | 3.22 | ||

| Socket No. | 1 | 1 | 2 | 2 | 2 | 2 | 3 | ||

| M | 2.51 | 3 | 4 | 4.4 | 4.8 | 5.3 | 6.6 | ||